In the realm of crafting and design, 3D printing has opened up a myriad of possibilities, offering enthusiasts the ability to bring their creative visions to life in tangible form. One such application of 3D printing technology is the creation of embossing plates, which are used to add intricate designs and textures to various materials such as paper, fabric, and even metal. Let’s delve into the world of 3D printed embossing plates and explore how they are made, their applications, and the advantages they offer.

Contents

Understanding Embossing Plates

Embossing plates are tools used in the process of embossing, a technique that involves creating raised or recessed patterns on a surface. These plates typically feature intricate designs, textures, or patterns, and are pressed onto the material to leave a lasting impression. Embossing plates are commonly used in various industries including paper crafting, textile design, leatherworking, and even in the production of custom packaging and signage.

How 3D Printing Revolutionizes Embossing Plates

Traditionally, embossing plates were manufactured through methods like engraving, etching, or CNC machining, which could be time-consuming, costly, and limited in design complexity. However, 3D printing has revolutionized the production of embossing plates, offering several key advantages:

- Design Flexibility: With 3D printing, intricate and highly detailed designs can be created with ease, allowing for greater creativity and customization. Designers can experiment with various patterns, textures, and motifs to achieve their desired aesthetic.

- Cost-Effectiveness: Compared to traditional manufacturing methods, 3D printing offers a more cost-effective solution for producing embossing plates, especially for small-scale or custom projects. This makes embossing accessible to a wider range of enthusiasts and businesses.

- Rapid Prototyping: 3D printing enables rapid prototyping, allowing designers to quickly iterate and refine their designs before final production. This accelerated design process can save time and resources, particularly in product development and testing.

- On-Demand Production: With 3D printing, embossing plates can be produced on-demand, eliminating the need for large-scale manufacturing runs and reducing inventory storage costs. This flexibility enables businesses to respond quickly to customer demands and market trends.

Creating 3D Printed Embossing Plates

The process of creating 3D printed embossing plates involves several steps:

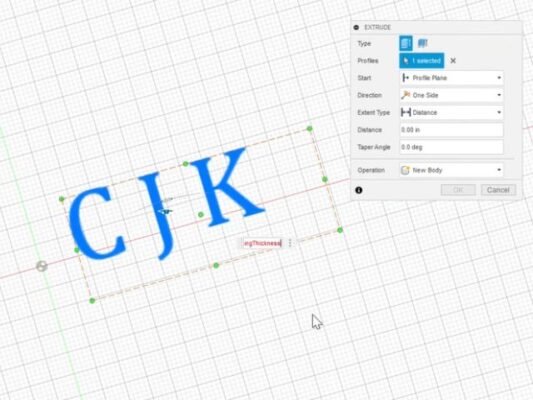

Design Preparation

Designers start by creating or selecting a digital 3D model of the desired embossing pattern using computer-aided design (CAD) software. This model defines the shape, depth, and intricacies of the embossing plate’s design.

Slicing

The 3D model is then sliced into thin layers using slicing software, which generates the instructions (G-code) needed for the 3D printer to create each layer. Parameters such as layer height, infill density, and print speed are configured based on the desired quality and material properties.

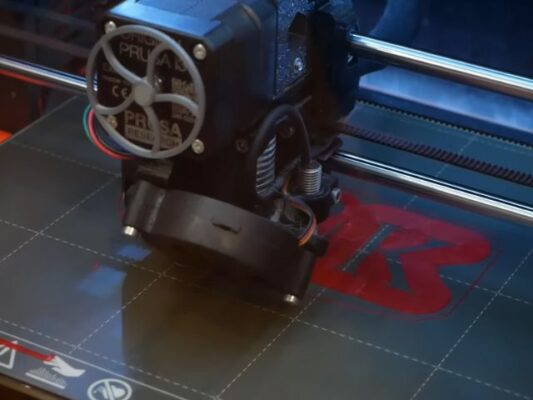

Printing

The sliced layers are sent to a 3D printer, which gradually builds up the embossing plate layer by layer using a suitable printing material such as PLA, ABS, or resin. The printer follows the instructions to deposit the material in precise locations, gradually forming the embossing plate’s design.

Post-Processing

Once printing is complete, the 3D printed embossing plate may undergo post-processing steps such as sanding, polishing, or coating to enhance its surface finish and durability. Additionally, any support structures used during printing are removed, and the plate is inspected for quality.

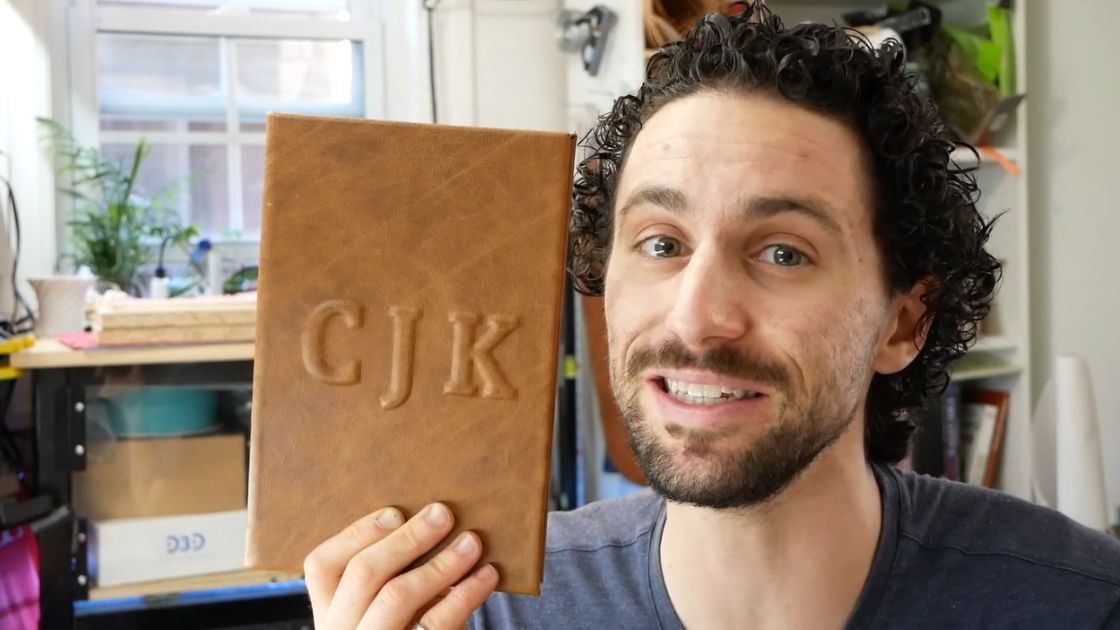

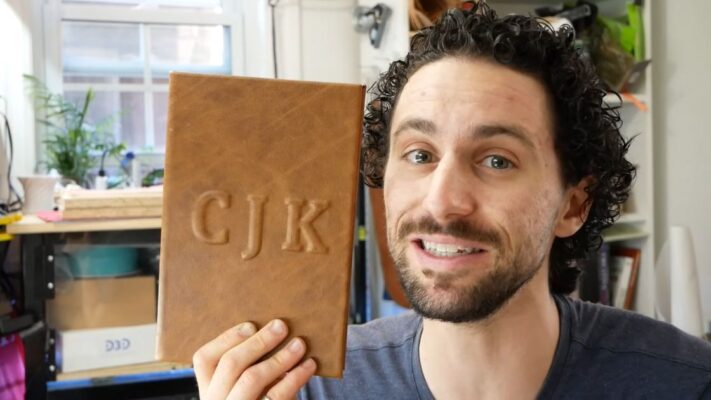

Testing and Application

Finally, the 3D printed embossing plate is tested on the intended material to ensure that it produces the desired embossed effect. Once validated, the plate can be used in various applications such as embossing paper for stationery, imprinting logos on packaging, or adding textures to fabric for fashion design.

Applications of 3D Printed Embossing Plates

The versatility of 3D printed embossing plates makes them suitable for a wide range of applications, including:

- Paper Crafting: Embossing plates are commonly used in card making, scrapbooking, and other paper crafting projects to add decorative elements and textures to paper and cardstock.

- Textile Design: In the fashion and textile industry, embossing plates are employed to create intricate patterns and textures on fabrics, leather, and other materials, enhancing the visual appeal of garments and accessories.

- Packaging and Branding: Businesses utilize embossing plates to imprint logos, patterns, or text onto packaging materials such as boxes, bags, and labels, adding a premium and tactile element to their branding.

- Art and Design: Artists and designers leverage 3D printed embossing plates to experiment with texture, form, and surface decoration in their artwork, sculptures, and mixed media projects.

- Customization and Personalization: With 3D printing, embossing plates can be easily customized to suit individual preferences, allowing for personalized products and gifts

In conclusion, 3D printed embossing plates offer a revolutionary approach to crafting, design, and manufacturing. With their precision, flexibility, and cost-effectiveness, these plates empower creators to add intricate textures and patterns to various materials. As technology advances, we can expect further innovations in embossing and surface decoration, ushering in new possibilities for artistic expression and product customization.

Related Posts